ENGINEERING SERVICES Űripari fejlesztésekFöldi kiszolgáló eszközökHadiipari fejlesztésekReliable products

ENGINEERING SERVICES Space industry development Földi kiszolgáló eszközökHadi ipari fejlesztésMegbízható termék

WE BRING YOUR IDEAS TO LIFE

With more than 10 years of development experience behind us we joined an industry, where expectations constantly change and become stricter every year.

In the space industry, Our first successful MASAT-1 mission was followed by many more in the field of flying instruments and ground service equipment (GSE).

In the aviation and military industry, we perform excellently in several development projects, meeting the highest safety and technical expectations in the area of development and production.

We support our Partners throughout the whole development process from their ideas to manufacturing.

References

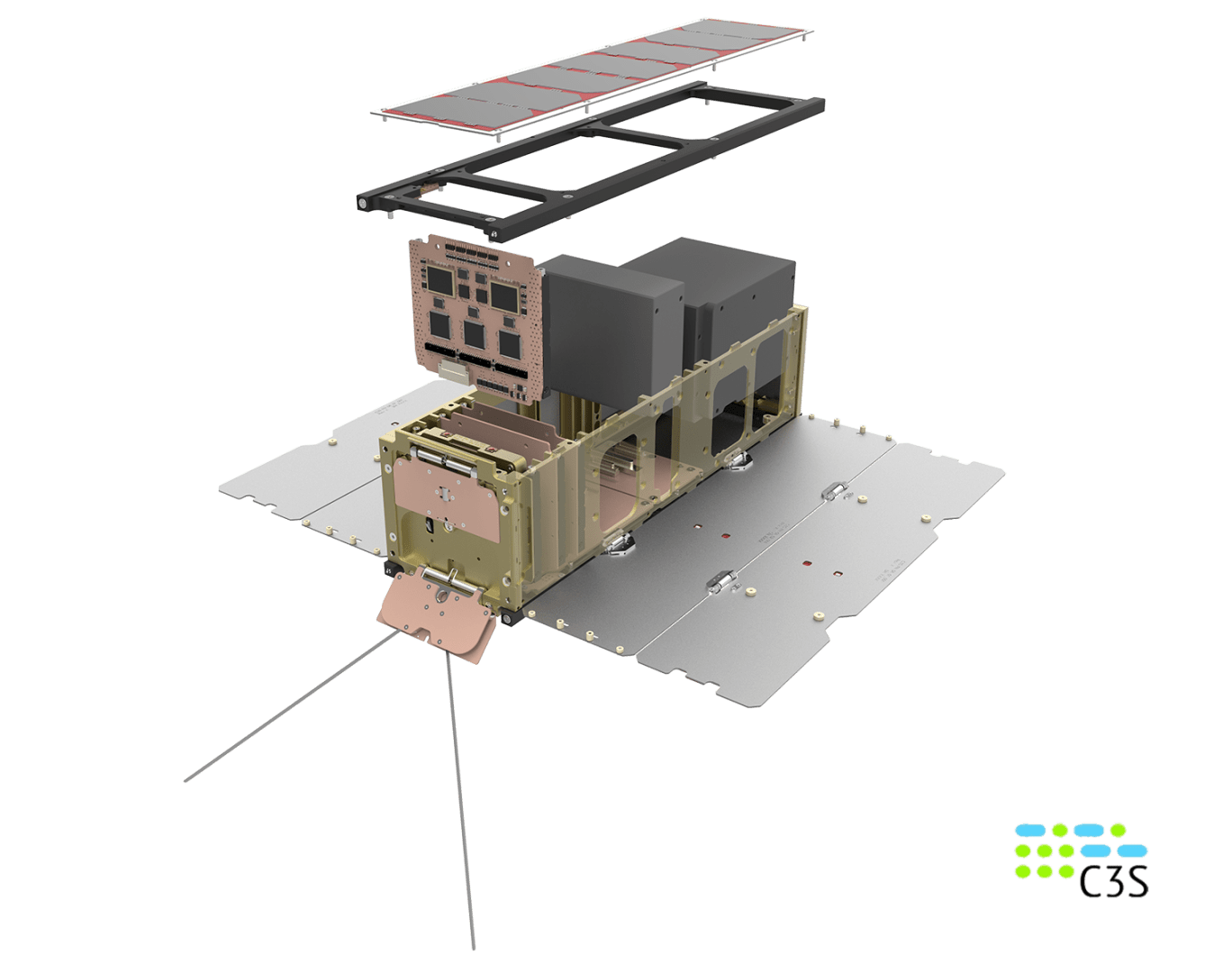

3/6U CUBESAT platform development

Small satellites can accommodate a significant payload. The goal of this project was to develop a safe and reliable platform, that provides the basis for various missions for which "only" the development of the payload will have to be carried out.

Our task was to design the mechanical elements connected to the platform. One of the biggest challenges was solving the opening mechanism of the solar panels and antennas that open in orbit around the earth.

The communication module, like all the cards, was attached to the rail system with a clamping element (Card-Lok). This unit has been provided with a dedicated inner casing for thermal and radiation protection as well.

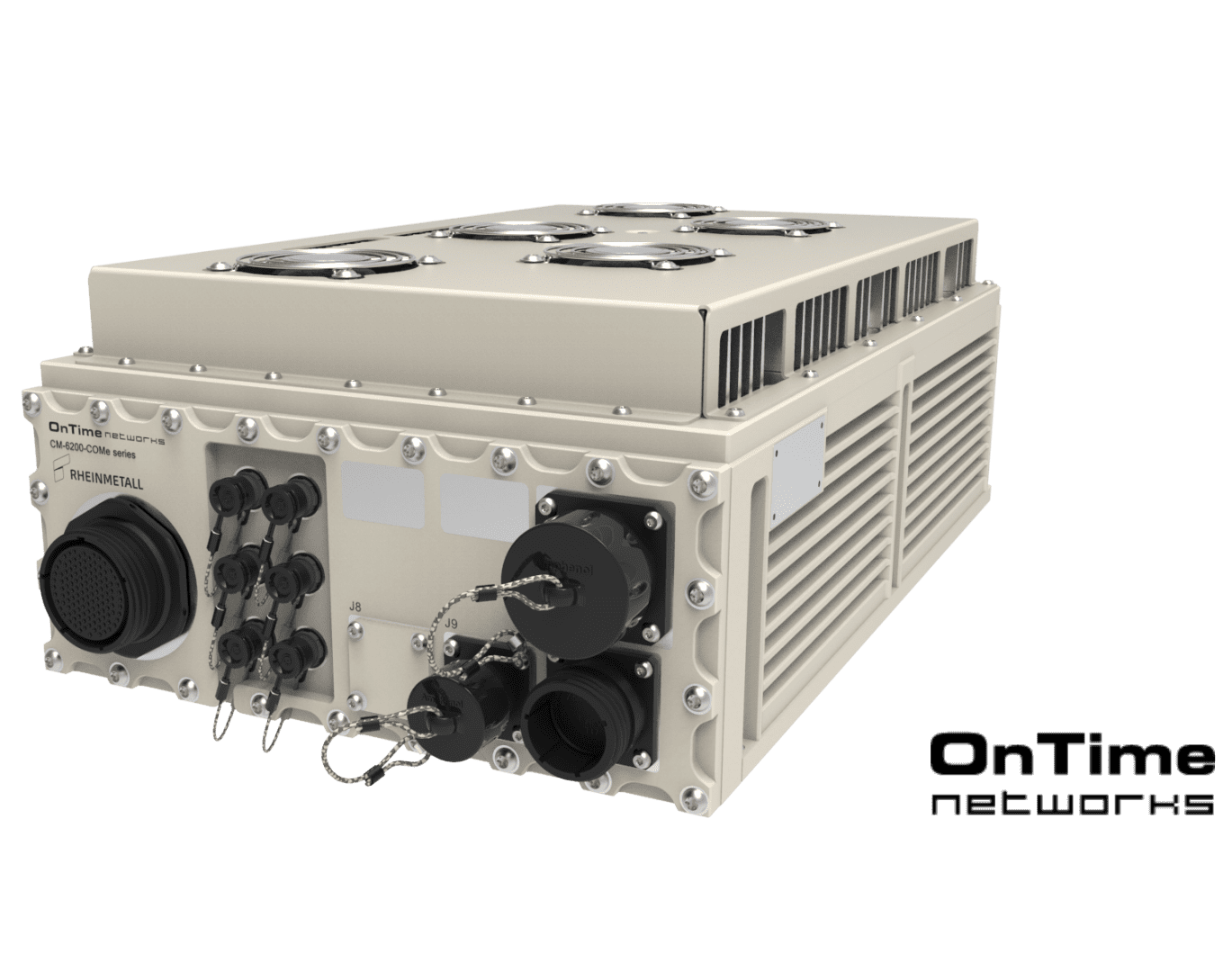

The development and production of Cloudberry COMe

As a first step. our task was to develop the Cloudberry MIL CM-6200COMe product in close cooperation with the electronics development team (housing design, assembly, manufacturing accuracy, ensuring thermal balance, etc.).

Beyond producing the prototypes Our company, CAD-Terv has carried out the small series production of the device's mechanical elements.

The development and production took place according to military industry requirements and standards.

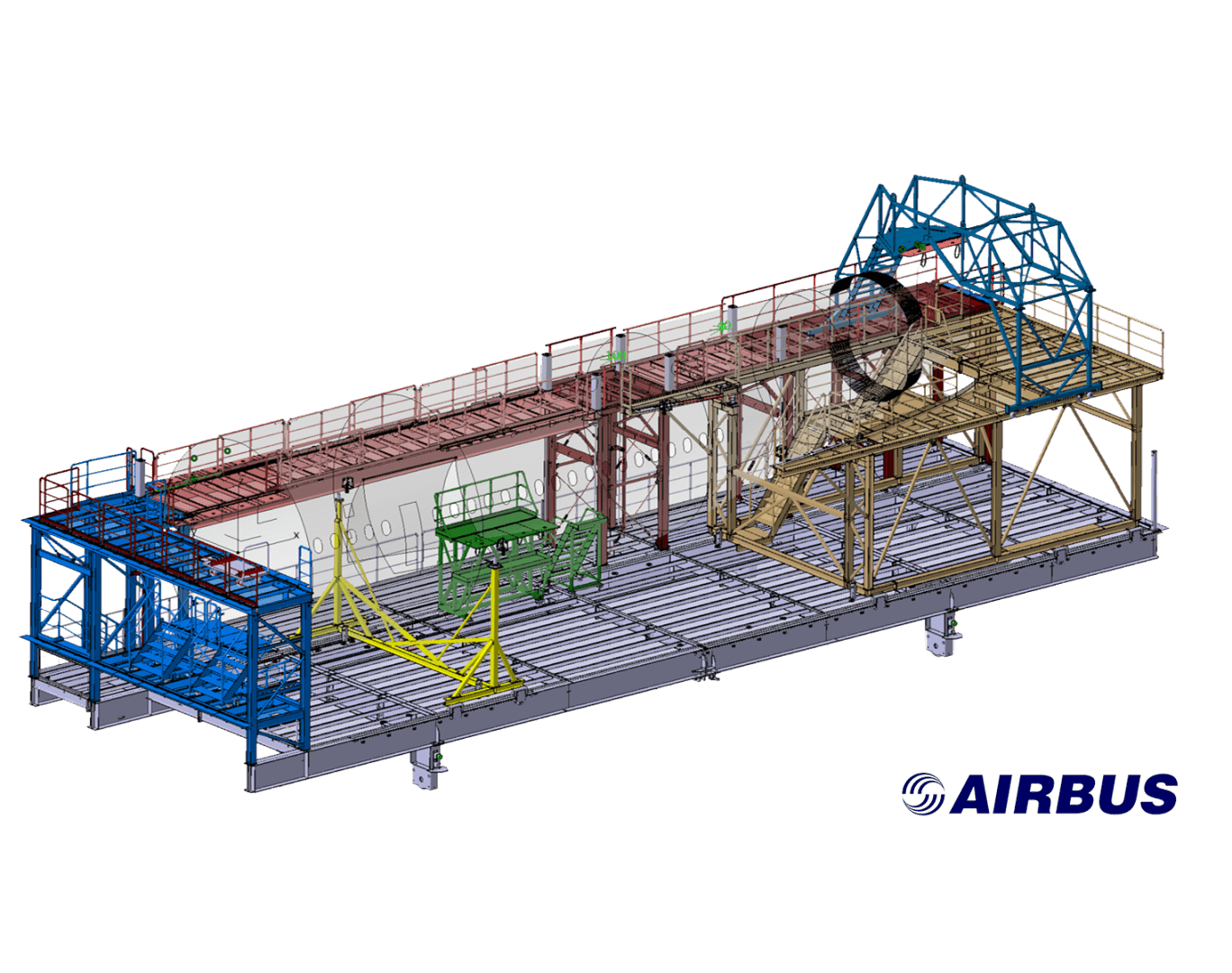

Assembly station development for AIRBUS

In order to speed up the process of aircraft manufacturing CAD-Terv has developed a line

of production equipment for a complete hall including a multi-level logistics platform and the design of assembly stations.

The main goal of this project was to find a solution, which allows to complete half an aircraft fuselage every 11 hours which we achieved by developing flexible assembly stands. Each station had to be compatible with multiple Airbus aircraft types in order to support operations on fuselage parts throughout the pre-assembly process.

Furthermore, the structure had to fit in with the existing halls, ensuring work on several levels.

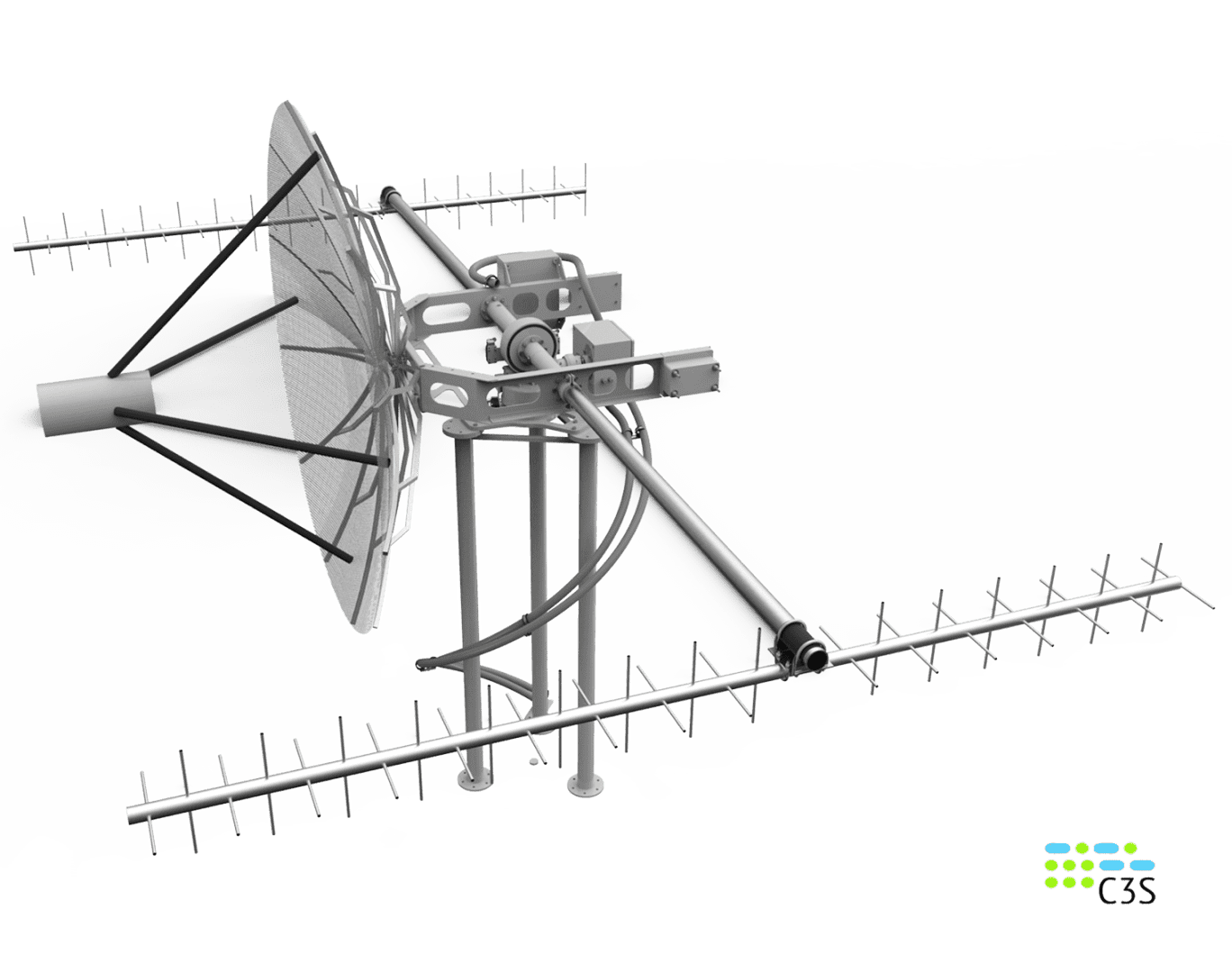

Development and production of an antenna rotator

The role of the ground service units (GSE) is at least as important as the satellite itself. Our task was to develop and manufacture an antenna system supporting communication and data collection with small satellites.

Special attention had to be paid to universality and flexible setting options. The system must work reliably in all weather conditions, therefore we had to take into account the effects of wind load, different temperature fluctuations and precipitation.

During the development, the different needs of certain areas had to be coordinated (such as satellite developers, house owners, operators, occupational health and safety, quality assurance, etc.), followed by the manufacture and operational installation of the device.

Why Choose Us?

Expertise

More than 25 years of development experience in a wide range of industries

Precision

We aim for the best quality possible, exceeding our partners expectations

Customer-focused approach

We place great emphasis on effective communication and to meet our partners requirements

Flexibility

Independent, proactive work according to the working methods of our partners